적용사례2-무선진동_온도 상태모니터링시스템(Wi-care): 크러셔 유성기어

Wi-care wireless vibration and temperature condition monitoring system

Friction and lubrication under control: fan in a chemical plant 화학공장에설치된 팬설비의 마찰과 윤활문제

Introduction

Vibration analysis online is the natural evolution of vibration analysis. Vibration analysis was first applied by the use of portable data collectors and data recording gathered from the route. Depending on the condition monitoring program, the manual data was collected periodically from 2 weeks to 6 months. With technology changes, the need to monitor machine status more closely and even to get data continuously is increasingly common. Online vibration monitoring systems were developed for this need. Their performance is at least equivalent or superior to portable systems. However their main advantage is the ability to access data at any time. Wireless vibration monitoring removes some of the major drawbacks of previous systems such as time and installation costs associated with a wired system. A wireless online condition monitoring system offers the possibility to extend your predictive maintenance strategy to the complete plant where wired systems typically protect production assets. The following case study describes and explains a typical remote analysis application of continuous friction/lubrication monitoring on a fan assembly. The continuous surveillance was set up in a very effective way for the customer and analyst : For the Customer: Easy detection, fast diagnosis and monitoring from the friction issue on a critical fan with low upfront investment and lower costs than manual/traditional online monitoring. For the analyst: Continuous data, instant trend data and 24/7 protection, higher confidence without any travel or measurement time spent The world is turning wireless, condition monitoring too! Equipment, plant overview, Context

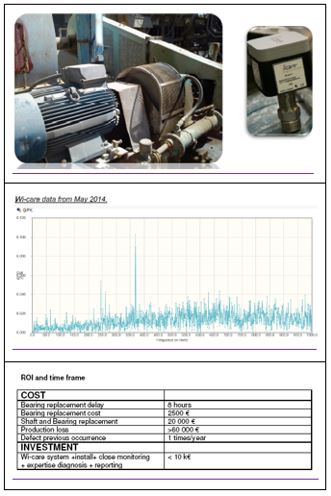

The Chemical site is a Phosphoric Acid Plant operating 24 Hours 7 days a week, established for many years in Africa. The Equipment in question is a large mixer involved in the acid production and a very large fan for production air treatment. Routine measurement performed with potable data collector indicated friction on both of these machines bearings. Cage frequency issues were detected, indicating higher than normal levels of friction. These raised levels would not warrant an immediate replacement but the next planned shutdown was in 10 months time. I-Care suggest the installation of Wi-care wireless vibration/temperature monitoring system and the analysis/trending by its remote team to ensure no premature escalation in the evolution of the defect.

The Wi-care system is set up with two sensors, one on the bearing supporting the coupling disc and one on the fan bearing wheel side. 시스템은 두개의 센서로 구성되어 있으며 하나는 커플링측 베어링 지지대에 나머지 하나는 팬 베어링 반부하측에 설치하였다. Displayed below is the standard spectrum collected with the Wi-care wireless monitoring system on vertical direction on fan bearing. Display in acceleration unit G PK. The spectrum shows a random noise vibration indicating friction inside the bearing. Some peaks (including the dominant one at 375 Hz) are related to ball frequency. 스펙트럼은 랜덤 노이즈 진동현상을 나타내고 있으며 이 것은 베어링 내부에서 발생하는 마찰을 의미하고 있다. 375Hz를 포함한 주요 피크 주파수는 베어링 볼 주파수와 관련이 있다. The level of friction is low (3 times lower than 6 months before). 진동의 레벨은 6개월전 보다 3배정도 더 낮게 나타났다.

TEL: 02-6480-9991 sales@astint.co.kr, Copyright. 에이에스티(AST) www.astint.co.kr

Wi care, I care, 방폭무선센서, 무선진동센서, 스펙트럼 무선전송, 인터넷기반, 설비진단, 진동문제, 원격진단

CUSTOMER > 자료실

CUSTOMER > 자료실