적용사례-무선진동_온도 상태모니터링시스템(Wi-care):크러셔 유성기어

무선진동 온도 상태모니터링시스템을 통해 시멘트 크러셔 유성기어박스의 돌발사고를 미연에 방지했던 사례 Wi-care wireless vibration and temperature condition monitoring system.

Prevention of a catastrophic failure on a cement crusher planetary gearbox Introduction

완벽한 솔루션이란 완벽한 감시를 하여 완벽한 진단을 할 수 있는 전문가가 주위에 있는 경우이다. In a perfect world, the easiest solution to ensure maximum production uptime, would be for all industry experts to live onsite around the clock! With the aim of ensuring that dedicated experts are always in the neighborhood, I-care created its condition monitoring remote diagnosis solution. The Wi-care wireless condition monitoring system performs online, real-time analysis of a particular machine to predict eventual failure. 이 시스템은 상시 감시 모니터링이 가능한 전문가에 의해 진단한 결과 The system performs he onsite data collection while certified analysts analyse your data offsite to deliver comprehensive recommendations 24/7. This wireless and remote strategy offers cost savings over routine-based maintenance and a very flexible solution for troubleshooting and monitoring. The following case study represents a typical remote analysis application of a gear defect. The fault was detected in a very effective way for the customer and analyst : For the Customer: Continuous surveillance of its critical asset with low upfront investment and lower cost than manual/classic online monitoring 분석가는 측정시간에 낭비할 필요없이 지속적인 데이터 축적이 필요하다.For the analyst, Continuous data (Historic and Remedial Action Recommendation) from the monitoring Center without any travel or measurement time spent 최근 전세계적으로 무선시스템의 유행이 번지고 있으며 상태모니터링도 예외가 아니다.The world is turning wireless, condition monitoring too! Equipment, plant overview, Context The Manufacturing site is a Cement Plant operating at close to full capacity, established for many years in Western Europe. 대형 시멘트 볼밀기계구성요소로 기어박스가 설치된 설비The Equipment is a very large cement ball mill. The suspected machine components are the gearbox and its associated electrical drive (1MW). 고객은 진동이 증가하여 의뢰하였고 무선 스펙트럼 전송 센서인 Wi-care를 설치하였고 무선으로 원격에서 진동의 증가 원인을 분석하였다.The Customer requested I-Care support after a suspected increase in vibration level. In order to do an in-depth and concise monitoring and diagnosis of the vibration on the complete assembly, the analyst decided to install Wi-care wireless system.

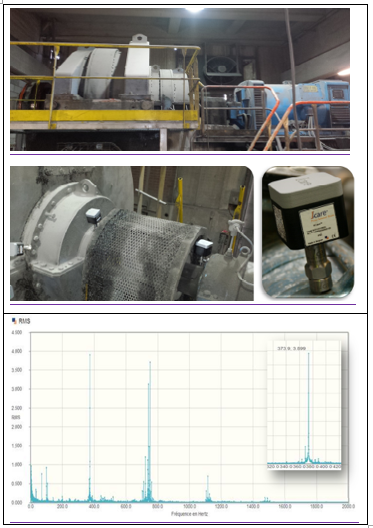

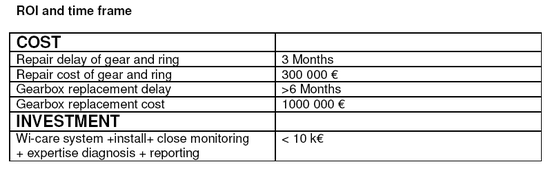

분석가의 진단과 스펙트럼은 기어주파수가 진동의 원인이라는 것을 확인하였다. Analyst diagnosis and spectrum justification: Gear frequency, The Wi-care system is set up on the gearbox and the electrical drive in minutes using magnetic locators to cover classical vibration directions, vertical, horizontal and axial planes. Note on the right side of the picture the Wi-care speed sensor directly measuring with a key-phasor on the shaft. Standard spectrum collected via Wi-care in the vertical axis. Display in speed units. 주요주파수는 373Hz로 그 하모닉이 존재하며 5Hz의 사이드밴드가 존재한다. 진폭은 4 mm/sec RMS .The dominant frequency appear at 373,9 Hz and its harmonics. On a closer zoom on 373,9 Hz appears modulation at 5Hz. The amplitude is close to 4 mm/sec RMS.

Following on from inspection of the drawings and data sheets, we can find the gearbox specifications and calculate theoretical fault frequencies

분석한 결과 GMF(기어의 맞물림주파수)로 확인되었고 5Hz는 링기어의 회전결함으로 파악되었다. Calculated Gear mesh frequency of 373,71 Hz and its harmonics match the measured frequency of 373,9 Hz. Detected 5Hz modulation are linked to a ring defect (5.01 calculated). 진폭 trend는 몇일 사이에 두배로 성장하였고 Amplitude trend indicate a 100% growth in a few days. The decision was taken by the customer based on analyst recommendations via Wi-care measurement to initiate the maintenance inspection. 근본원인은 조립불량에 이은 과도한 기계적이완(looseness)로 인한 구조의 크랙발생인 것으로 판단되었다. The Root cause of the gear defect is an excessive looseness in the gear assembly due to structural cracks.

Wi care를 이용한 설비진단의 결과, 투자대비 회수율 ROI

TEL: 02-6480-9991 sales@astint.co.kr, Copyright. 에이에스티(AST) www.astint.co.kr

Wi care, I care, 방폭무선센서, 무선진동센서, 스펙트럼 무선전송, 인터넷기반, 설비진단, 진동문제, 원격진단

CUSTOMER > 자료실

CUSTOMER > 자료실