적용사례-초음파 누출진단기 Leak shooter

초음파의 음향방출(Acoustic emission)을 이용한 누출진단기는 그 발생위치를 가청음을 통해서 진단할 뿐만 아니라 최근에는 카메라를 통해서 그 위치를 직접 알 수 있도록 하는 기술로 발전되고 있으며 다음의 사례를 통해서 그 적용을 알아본다.

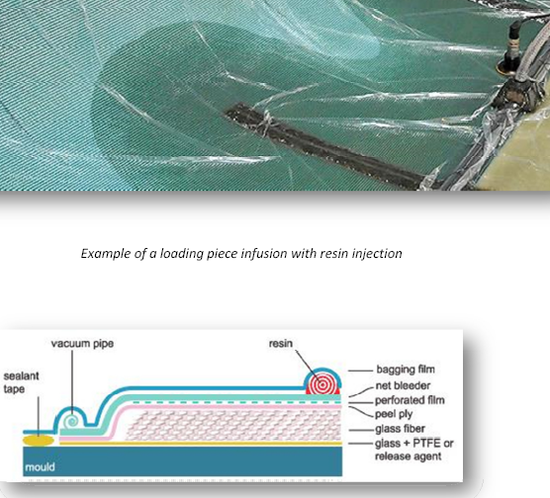

다음의 적용사례는 주입공정에 사용되는 진공의 누출로 항공 및 선박 또는 터빈블레이트나 유사 파트에서 잘 나타나는 현상에 관한 것이다. Looking for vacuum leaks in infusion process used in: Construction of composite parts for aerospace industry, construction of composite boats hulls, construction of composite wind turbine blades and other composite parts.

진공주입공정에서의 문제점(SCRIMP)

Problem encountered with vacuum infusion (also named SCRIMP method):

진공주입방법은 몰드, 유리섬유 커버 및 다른 진공장치에 필수적인 구성요소 안에 레진을 주입한다..Vacuum infusion method consists to inject resin in a closed structure composed of an open mold, topped with a hermetic cover which contains glass fiber or other and all together connected to a vacuum installation. 레진을 섬유를 주입하기전에 우선 일정한 진공압력으로 진공상태를 시험해야한다. Before infusing the fiber with resin, firstly we have to be sure everything under vacuum pressure (almost between -0.5 et -0.9 Bar) is leak tight. 이 때 플라스틱 커버안에 누출이 발생하였다면 레진이 유리섬유에 골고루 분포 확산되지 않으므로 제품의 마감처리가 불완전하게 수행된다. If there are leaks in the plastic cover, then the resin dispersion will not be uniform in the glass fiber which will result in imperfections in the finished product. 특히 레진주입기의 삽입부근에 누출이 생기면 레진이 누설되고 공정자체가 실패하는 것이고 또한 비용에 직접적인 연관이 있는 생산에 차질이 생기게 된다.If there are leaks on or around the inlet connector resin injection, there will be resin loss, efficiency loss in the infusion process, so time loss, production loss and ultimately a reduction of profit. Vacuum leak detection solution:

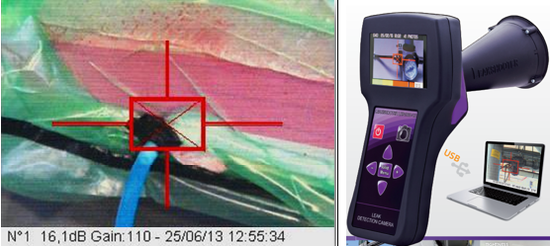

With the LEAKSHOOTER LKS1000, equipped with combined vision/ultrasonic detection technology with standard cone use, 1m 떨어져서도 쉽게 스캐닝하여 누설된 군(Zone)을 우선 파악하고 난 후,그 구역을 특정센서를 이용하여 더 세부적인 봉인된 위치나 인입구 등의 누설여부를 알 수 있다. it is possible to easily detect these leaks by scanning the upper zone sheeting, the holding seals, the inlet connector… around 1 m away. Then, when the zone leak is identified with the cone, it is possible to approach it and connect the flexible probe to finely check the leak and carry out necessary repairs. 이러한 전체 누출확인절차는 헤드폰이 필요없고 계측기의 화면에 누출위치를 표기하고 있으므로 매우 유용하고 효과적인 방법이다. This whole procedure can be realized with or without the headphone, thanks to the automatic and dynamic target on screen during leak detection (see below).

Leak shooter 초음파 누출 진단카메라를 통한 누출위치의 판독 적용사례

TEL: 02-6480-9991 sales@astint.co.kr, Copyright. 에이에스티(AST) www.astint.co.kr

초음파, 공기누출, Leak shooter, Synergy

CUSTOMER > 자료실

CUSTOMER > 자료실