초음파 감지계측은 지난 25년간 다양한 산업현장의 예지보전분야에서 지속적으로 광범위하게 사용되어왔습니다. 또한 최근에는 보전부서의 큰 발전과 아울러 진동,소음,온라인모니터링, 누설, 전기문제 등의 장비보강과 기술축적에 큰 진전을 가져왔습니다. 특히, 초음파 진단은 그 과정이 설비예지보전기술에 포함되어 있는냐 없는냐 ?에 따라 얼마나 현실적이고 완벽하게 장비를 갖추고 있는가를 판단하는 기준이 되고 있습니다.

현재 산업현장에서의 화두는 "Cost Saving"에있으며, 초음파 설비진단기를 사용함으로써 얼마나 고장진단을 정확히하는가?가 중요하다 할 수 있습니다. 전세계의 설비보전분야에서 사용되고 있는 놀라운 SDT의 활용도와 여러가지 적용사례등을 통해 그 사용도를 이해하실 수 있을 것입니다.

- Leaks (detection and localization)

! 적용산업분야

Bearings

좋은상태,나쁜상태 또는 신품, 중고를 막론한 모든 베어링부품은 구름요소가 내륜,외륜에 걸쳐 움직이므로써 초음파 마찰음이 발생하게 된다. 물론 좋은 상태의 베어링은 마모로 인한( pitting, spalling, flattening of the balls, and scarring of the raceway) 음향에너지의 발생이 적은 편이다. 마찬가지로 그리스로 마찰을 잘 흡수한상태 즉, 윤활이 잘된 베어링은 마찰음이 적다. 윤활제의 점성이 약화될 때, 베어링의 물적 응력과 피로상태, 마찰은 초음파의 방사량을 증가시키게 된다. 위와같은 고주파 음향과 진동을 초음파진단시스템으로 잘 관찰하게 되면, 적당한 윤활주기을 결정하고, 베어링의 1차마모 진입시기를 예상할 수 있다.

음향진동의 관찰과 진동분석의 차이

음향진동(Acoustic vibration)값과 '저주파대역 진동측정'은 서로 혼동하여 이해하지 않아야 한다. 저주파수대역 진동측정(속도와 변위)값은 마모가 이미 진전된 상태를 나타내며, 근본적인 결함원인인 질량불평형이나 축정렬불량상태(misalignment, imbalance, etc.) 등에 대한 정보를 제공할 뿐이다. 따라서 진동에 의한 베어링의 측정 은 이미 결함진전상태에 있기 때문에 '설비를 언제 정지시켜서 교환해야 하는가?"를 결정할 만한 단서를 알려줄 뿐이다. 반면에 고주파수대역인 음향진동에 대한 측정과 관찰은 베어링의 진전상태를 제어함을 가능케하며, 윤활의 주기를 지시해주며, 베어링이 '파손상태'로 이르기 이전에 트리거알람(triggers alarm)을 발생시킬 수 있다.

변화량을 초기에 감지해서 정확한 액션을 취해준다면, 기계설비의 수명연장에 직접적인 영향을 줄 수 있다. 본 공장의 예지보전(predictive maintenance)의 목표가 '생산기계의 수명연장'에 있다면 초음파검사는 반드시 있어야 하는 과정이어야 한다. 아직까지 어떠한 설비의 상태감시기술로도 초음파와 같은 초기 경고상태를 직접적으로 주지 못하고 있다.

The Technique

베어링의 상태를 감시하는데는 SDT 170 M or 170 MD모델에 포함된 ' contact mode'를 활용하면 된다. 적용상태에 따라 다르지만 기계적인 주파수는 주로 Contact Probe를 사용하게 된다. 접촉 방식에 따라 자석식 센서도 사용할 수 있다.

SDT 170에서 측정된 초음파의 음향에너지(Ultrasonic acoustic energy)는 사용자가 이전 측정값과의 비교상태를 3 cm x 6 cm LCD화면에서 확인할 수 있다. 또한 동시에 초음파 신호는 헤드폰을 통해 가청신호로 변환되어 들을 수 있다. 이때 측정자가 실제로 듣게 되는 초음파는 일반적인 가청주파수방식 (광대뼈에 스크류드라이버를 들이대고 의사가 청진기로 듣게되는 음)의 진동음(parasitic sounds)을 듣게 되는데, 이 것은 대부분의 강력한 분석도구와 같이 질적인 그리고 양적인 정보를 같이 제공하고 있다고 할 수 있다.

처음으로 돌아가 보면, 이 측정의 목적은 베어링의 정상적인 상태값이 얼마인가?를 측정하고 베어링의 결함이 진척되고 있을때(윤활상태가 파괴되거나,구조적으로 파손) 어느 정도 음향에너지가 증가하는가?에 있다고 할 수 있다. 정상적인 상태의 베어링은 상대적으로 +/- 4 or 5 dB m V의 초음파 발생을 유지해야 한다. SDT 170은 이 변동된 증가량을 읽고 Data Logger software를 통해서 음향에너지의 경향자료를 비교하여, 베어링에 윤활을 해야할 시기를 정확히 예상할 수 있으며, 베어링의 초기결함상태를 확인할 수 있다. 이 때, 음향에너지의 진폭경향을 통해 베어링의 변화신호를 그 어떤 도구보다도 빨리 알려준다는 것에 큰 장점이 있다. 이 정보를 잘 사용하게 되면 윤활의 직접적인 활용과 베어링의 수명을 늘리는데 큰 도움이 될 수 있다. 또한 가장 중요한 것은 수리계획을 작성하는데 가장 정확한 정보의 창이 된다는 것이다. SDT 170의 사용을 최적화하기위해 베어링의 음을 듣는 것은 반드시 필요하다. 베어링에서 나오는 잡음을 잘 들어보면 중요한 정보를 제공한다는 것을 확인 할 수 있을 것이다. 즉, 규칙적인 잡음은 정상적이고 안정된 상태를 나타내고, 불규칙적인 피크 값을 가지며 귀에 매우 거슬리는 음(strident high pitched noise)은 윤활의 부족상태나 과부하, 베어링이 회전수에 맞지 않는 상태를 나타낸다. 또한 불안정하며 높은 dB값을 가지는 '딱딱거리는 소리( crackling noise)'는 파손,마모,윤활제에 금속파편이 섞인상태를 나타낸다. 디지탈로 표현되는 dB값과 헤드폰에서 들리는 음을 같이 비교함으로써 확한 '예지보전' 분석기술임을 확인 할 수 있을 것이다.

Comparative vs Correlative Technique

베어링은 제품마다 제각각 다른 독특한 소리와 초음파를 발산하는데 이 값들은 SDT170에서는 ' dB m V'로 표현한다. 또한 이 방사량은 아래의 요소들에 의해 직접적으로 관련이 있다.;

- The type of bearing 베어링의 형식: with needles, conical, with balls or rolls (single or double);

- The diameter 직경;

- The rotation speed 회전수;

- The load 하중;

- The lubrication 윤활;

- The mounting 마운팅;

- The envelope features 변조특성;

- The environment (heat, dust, humidity) 설치환경.

다시 말하면, 특정 베어링을 측정한 값으로 비교할 수 있는 어떤 '차트'가 있는 것은 아니다. 두개의 이상적인 베어링이 있다고 하더라도 각기 다른 환경에 설치가 되었다면 각기 다른 음향적인 방사(acoustical emissions)를 하게 된다. 상태모니터링프로그램( condition monitoring program)을 가동하게 되면 유사기계를 비교할 때 유용하게 사용된다. 하지만 위에 언급한 요소들과의 관련성을 가지려면 신뢰할 수 있는 결과가 있어야 한다. 결국, 각기 다른 환경의 베어링에는 정상적인 상태의 음향진동의 수준을 측정하고, 현재의 초음파 값과의 trent데이타를 비교하는 것이 최선의 방법임을 알 수 있다.

일반적으로 '위험작동수준(critical)'의 경계는 기초값에 비교해서 15 dB m V로 한다. +8 - +10 dB m V는 윤활상태에서 '극적인 변화( dramatic change)'를 예상할 수 있다. 새로운 윤활제를 적용할 때 베어링의 초음파를 들어보아야 한다.그리스가 베어링의 내부요소에 도달할 때, 헤드폰에서 들리는 음과 화면에 디지탈 값으로 측정된 값을 기초값과 측정해보자. 만약 음향진동의 수준이 윤활을 한 이후에도 높은 상태로 유지된다면 ,베어링이 초기결함상태라고 확신할 수 있다. (그리스가 그 베어링에 적절한지를 확인할 것).

Use of the contact probe (접촉식 초음파센서의 활용)

대부분의 상황에서, 접촉식 초음파센서는 베어링의 상태를 잘 파악할 수 있는 최선의 방법이다. (SDT 170M and MD모델에서는 표준구성품이나, 170S모델에서는 옵션사항이다.)

측정신뢰도를 높이기 위해서 아래와 같은 규칙을 따라야 한다;

- 탐침을 정확하게 조립할 것;

- 측정하는 부분은 항상 동일할 것(베어링 하우징에 측정된 부분을 펜으로 표시할 것);

- 측정포인트는 항상 직각으로 측정하며, 경사진 상태에서 측정을 피할 것;

- 측정할 때 일정한 압력을 유지할 것;

- 측정자료가 표준화 될때까지 약 3,4초간 'M+'버튼을 누르고 있을 것.

- 탐침봉의 주파수 설정은 보통 기계의 경우 "M" , 저속일 경우 (< 100 rpm) "SM"에 맞출 것.

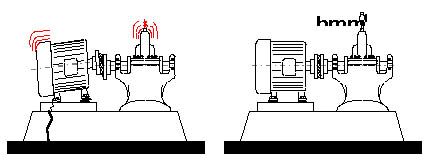

Coupling (alignment)

축정렬시 항상 여유상태가 존재하므로 커플링에서는 부드러운 특성인 호르라기 소리를 나타낸다(whistling sound). 또한 , 축정렬 불량상태일 때는 불규칙적으로 끊기는 단음( irregular noise staccato in nature)이 발생하게 된다.. The SDT 170 은 공정설비의 축정렬상태를 정기적으로 확인할 때, 아주 좋은 검사도구로써 활용할 수 있다.

커플링은 접촉식(contact mode)또는 마이크로폰식 센서(airbone mode)모두 측정이 가능하다.:

Contact Mode:

- 센서를 'MEC' mode로 설정한 후, 커플링 노이즈를 배제시키위해서 커플링의 앞 또는 케이싱 아래부분에서 측정한다. 이 때 모터쪽 방향에서 센서를 측정하지 말 것.

- 신호를 들어보면, 일반적으로 베어링의 초기마모가 있으면 55 dB이상의 값을 나타내며, 원인은 커플링의 정렬상태가 불량이기 때문이다.

Airborne Mode:

- SDT 170의 내장 마이크로폰을 사용해서 커플링을 스캔하거나, 외장 Flexible Sensor를 설치해서 헤드폰을 통해 불규칙적으로 끊어지는 단음을 들어본다.

모터,펌프,기어박스 등에서 발생하는 진동소음을 베제하기위해서 센서에 focus tip을 부착,활용할 것.

위의 진동소음을 배제시키는 방법으로 커플링의 안전케이싱의 안쪽에서(안전에 유의할 것) Flexible Sensor에 focus tip을 부착해서 측정해 보면 좋은 신호를 들어볼 수 있다.

Steel Tanks (압력용기)

금속제 탱크의 용접심부분에서의 누설은 탱크자체의 압력으로는 너무 작아서 직접 측정하기에는 초음파의 방법은 어려운 면이 있을 수 있다. 이 때에는 물이나 오일을 탱크의 표면에 스프레이하면 누설의 증폭효과를 이용할 수 있다. 즉, 작은 공기발울은 누설이 발생하는 곳을 알려주기도 하지만, 공기방울이 터질때, 고밀도의 초음파를 방사하게 되어, SDT 170의 내장센서나 플렉서블 센서를 통해서 쉽게 감지할 수 있다.

Hydraulic circuits (유압회로)

Operate as follows:

- 탐침봉을 밸브 몸체에 대고 측정을 준비한다.

- 밸브를 열고 밸브에 유체가 흐를때 발생하는 신호를 측정한다 (in dB m V).

- 밸브를 닫고 신호를 측정한다. (in dB m V). 밸브를 닫을 때 역류로 발생하는 난류흐름과 관련이 있다.

- 밸브를 열고 닫을때 값을 비교한다. 중요한 차이점을 발견할 수 있을 것이다.

충격흡수장치들( shock absorbers, rams, or cylinders)이 있는 시스템에서 누설이 있다면 그 것은 내부저항체(wiper or seal)을 가로지를 때 발생하는 공기방울이 형성되어 발생하는 현상으로 나타나게 된다. 압력을 가했을 때 뿜어져 나오는 누설은 즉 초음파를 발생하므로 감지하기 쉽다.

Compressor (압축기)

Piston (Reciprocating) compressors (왕복동 컴프레샤)

왕복동 컴프레샤의 작동상태는 밸브 마모상태에 크게 비례한다. 밸브내부에 오염물질(카본 또는 기타)이 끼었을 경우, 이를 감지하는 방법은 다음과 같다.;

- 매번 똑같은 측정포인트를 측정하도록 송곳이나 기타 마커로 밸브를 표시한다.

- 한달에 한번 탐침봉(MEC mode)을 사용해서 초음파를 측정하고, DataManager software를 이용하여 경향(Trend)를 파악한다.

- 밸브측정포인트 값이 증가추세에 있다는 것은 오염물질이 증가하고 있다는 것이다. 왕복동 밸브에 해당하는 보통상태의 기본 초음파 값은 70 ' 80 dB이상의 값을 초과할 것이다.

Screw compressors (스크류;나사식 컴프레샤)

스크류 컴프레샤의 볼베어링의 음향진동을 측정하고 듣는 것은 실제로 다른 기계의 베어링 값과 유사하다. 그러나, 측정하는 사람은 훨씬 큰 초음파 값을 가질 것이라고 예상하곤 한다. 스크류 컴프레샤 베어링에서 50 dB정도가 측정된다고 해도 크게 문제가 된다고 볼 수 없다. 왜냐하면 높은 값은 스크류에 공기흐름때문에 나타나는 것이기 때문이다. 다시한번 바로 위에서 언급했듯이 경향그래프(trend)를 이용해서 기준상태에서 10 to 15 dB m V정도 상위할 경우 파손상태를 예상할 수 있다.

Corona effect (코로나)

코로나효과(케이블의 전기아크음, 변압기, 엔진, line bushings, engine brushes에서 발생하는 계란 후라이 할때의 치직하는 음같은 초음파발생현상)로 인해 미세전기(Micro-electrical)가 발생한다. 이는 화재나 폭발을 유발하는 심각한 문제를 발생시킬 수 있다. SDT 170의 센서를 이용해서 코로나효과의 초기발생상태를 감지하고 문제발생의 소지를 방지할 수 있을 것이다.

Gears (기어)

Meshing of gears produces friction and acoustic vibrations are emitted. It is possible using the SDT 170 to monitor the condition of gears over time. The method is the same used for bearings.

Contact Mode:

______Select key areas on the gearbox housing and mark the measurement point with an awl for repeatability. Using the contact probe, listen for defective gears and other anomolies using comparitive techniques. Quantify the measured value and store it to the Datalogger for trending. Compare historical readings to spot a deteriorating condition. Be mindful of variables such as speed, temperature of oil, and load.

Airborne Mode:

- Listen to the signal by sweeping from one side of the box to the other using the airborne sensor. A good gear mesh produces constant and regular ultrasounds. A defective gear can be recognized by a high-pitched noise in the headset.

- Take measurements on each gear.

- Considering the diversity of the materials since it is impossible to give precise reference values for every size and type of gear in the marketplace. Use the comparison method when diagnosing gear problems, especially if a baseline has not been established.

Tightness control (emission/reception);기밀 (방사/허용)

초음파 감지를 이용한 다양한 사용은 예지보전뿐만 아니라, 품질제어기술(Quality Controls)로도 사용될 수 있다. 어떤 공간의 기밀상태(clean room, building, car, airplane, hatch covers of ships, submarine, bus, train, zero oxygen buildings etc.)의 유지관리는 중요한 검사이다. 이 검사기술로는 연기누설측정, 가압측정, 수중측정(smoke bombs, pressure decay, water shower) 등의 방법을 예로 들 수 있다. 또한 시간,자원,인력,정확성의 측면에서 훨씬 효율적인 초음파 측정기술이 있다.

An ultrasonic transmitter emits a controlled and stabilized level of ultrasound, normally in two overlapping frequencies. This ultrasonic emission is heard and measured with the SDT 170 M and MD. The wave structure of the ultrasound is such that it can penetrate extremely small orifices and thereby reveal the site of a leak in the structure being tested. The method is as follows:

- Place the transmitter inside the volume to be tested (car, airplane, ship, building etc.). Externally scan the volume and localize the passage of ultrasounds with the SDT 170's internal airborne sensor or flexible sensor. Pinpoint the exact location of the leak and measure it with the SDT 170. Comparisons can be made to determine the severity and size of the leak.

- If the dimensions of the volume allow it, try reversing the procedure by placing the transmitter outside and the SDT 170 inside.

Certain volumes, due to their shape and wall thickness, cannot be controlled by ultrasounds as they remain inside. Therefore an alternative solution has to be found:

- Air + ultrasounds: put the volume under pressure and localize the leaks by means of the detector. The detection limit is 4 cc per minute.

- Air + liquid developer + ultrasounds: this method is used when the pressure is under 1 bar (15 PSI) and when the leaks are smaller than 4 cc per minute.

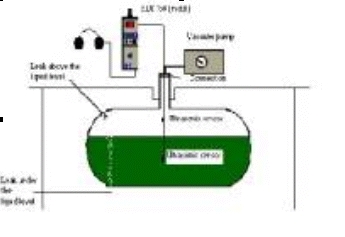

- Air + water + ultrasounds: put the volume under pressure and submerse into water. Any leak provokes a bubble and its burst produces ultrasounds even when the bubbles are scarcely visible. This method allows controlling the tightness of a volume but the origin of the leaks cannot be localized with precision.

- Vacuum + ultrasounds: if the volume permits, place it under vacuum after having previously introduced an ultrasonic sensor in it. The air penetration from______ a leak can be detected more easily as the volume constitutes a resonance chamber.

- Depression + liquid + sonic signal: by filling the volume with liquid prior to putting it under vacuum, any leak will provoke air bubbles that can be detected by means of a sensor placed in the liquid. This method combined with the previous one can be used when the liquid does not fill the entire volume. Example: Underground Storage Tanks

Leaks (detection and localization) ;누설(감지와 위치추적)

7 bar정도의 압력으로 압축기와 연결되어 있는 파이프 연결부 또는 기공이 발생하기 쉬운 부위(pipe openings, badly tightened join, porous flexible)에 직경 1mm정도의 공기누설구멍이 생겼다면, 5 m 3 /h정도의 누설량을 예상할 수 있다.한 포인트만 있다고 가정하더라도 1년이면 43 800 m 3 이라는 막대한 손실의 공기누설이 발생한다. 공기가 누설되는 것을 감지하는 것만으로도 재정 절감, 에너지절감 측면의 이익을 얻을 수 있다.

마이크로폰센서( airborne sensor )를 앞뒤로 잘 훑어보면, 헤드폰으로 누설되는 음을 들을 수 있다. 누설과 관련있는 히싱음( hissing sound;새어나오는)은 그 곳이 누설되고 있다는 명백한 증거가 된다. 초음파의 '직진특성'때문에 히싱음이 발생되는 곳을 찾는 것을 찾는 것도 쉽다. 바로 그때 필요하다면 간단한 응급처치도 할 수 있는 것이다. 똑같은 원리로 진공의 누설도 찾아낼 수 있는데, 단, 진공의 경우에는 탱크나 파이프의 안쪽에서 초음파의 발생량이 더 크게 발생하므로 약간의 경험과 기술이 필요하다.

Complex reducers (복합형 감속기)

- 결함있는 베어링을 찾기위해서 꼭 기계를 분해하고 그 곳을 측정할 필요 없이 다른 곳을 측정하여 설비의 상태를 알 수도 있다. 다음의 방법이 있다.:

- 윤활상태가 좋은 감속기;부드럽고 규칙적인 소음,40 dμB 보다 아래값.

- 윤활상태가 좋지 않음 감속기:어느정도 균일한 날카로운 노이즈,50 dμB 근처값.

- 기어의 문제: 딸깍대는 노이즈발생 60 dμB보다 큰 값.

- 베어링의 문제: 반경방향 ( radial)보다 축방향(Axial)에서 가장 큰 값이 측정되었을 때, 60 dμB보다 큰 값.

Valves

밸브가 열린상태에서 탐침봉( contact probe)으로 측정해보면 가스나 액체의 흐름을 알 수 있지만, 밸브가 닫혔다면 누설이 발생하지 않고서는 초음파가 발생할 수 없다. Operate as follows:

- 탐침봉을 대고 밸브의 움직임에 따른 변화량을 잘 들어본다.

- 신호가 계속발생한다면:

- 밸브가 열려있거나 또는

- 밸브가 닫혀있다면 누설되고 있다.

- 신호가 발생하지 않으면

- 밸브가 닫혀있거나 또는

- 밸브가 닫힌 상태이므로 밸브를 잘 살펴볼 것

어떤 종류의 대형 수동조작밸브는 두께가 너무 두껍거나 지탱하기 곤란해서 탐침봉으로 측정하기 어려운 경우에는 자석센서를 사용할 수도 있다.

누설시 발생하는 '초음파'와 밸브를 닫기전에 또는 컨덴서에서 발생하는 '난류음(turbulence)'을 구분하지 못해 혼동스러운 점이 발생할 수 있다. 누설은 항상 난류에 의해 발생되는 신호보다 더 높은 신호값을 가지며, 누설은 어떤 특정 한 점에서만 신호가 발생하는 반면에 난류는 설비의 전반적인 곳에서 발생한다. 이 차이점은 설명하기는 어려우나 공장에서 발생하는 몇개의 경우만 측정해 보아도 구분할 수 있다.

TEL: 02-6480-9991 sales@astint.co.kr, Copyright. 에이에스티(AST) www.astint.co.kr

고객센터 > 기술 자료실

고객센터 > 기술 자료실